Keeping trains running during summer heatwaves

Rail expansion due to seasonal heating is a common problem in railways. During a summer heatwave, rails in direct sunshine can be as much as 20°C hotter than air temperature. As rails expand due to the extreme heat, they can start to buckle. Extreme heat, over a two-day period in 2016, lead to nearly 200,000 delay minutes for Network Rail alone.

Complications when temperatures get too hot

When a section of track starts to buckle, local speed restrictions are required as slower trains exert lower forces on the track. Without speed restrictions there would be a severe risk of derailments or damage to infrastructure. Then the line has to be closed for repair. Both speed restrictions and repairs disrupt journeys, something you do not want to happen.

The solution is real-time insight

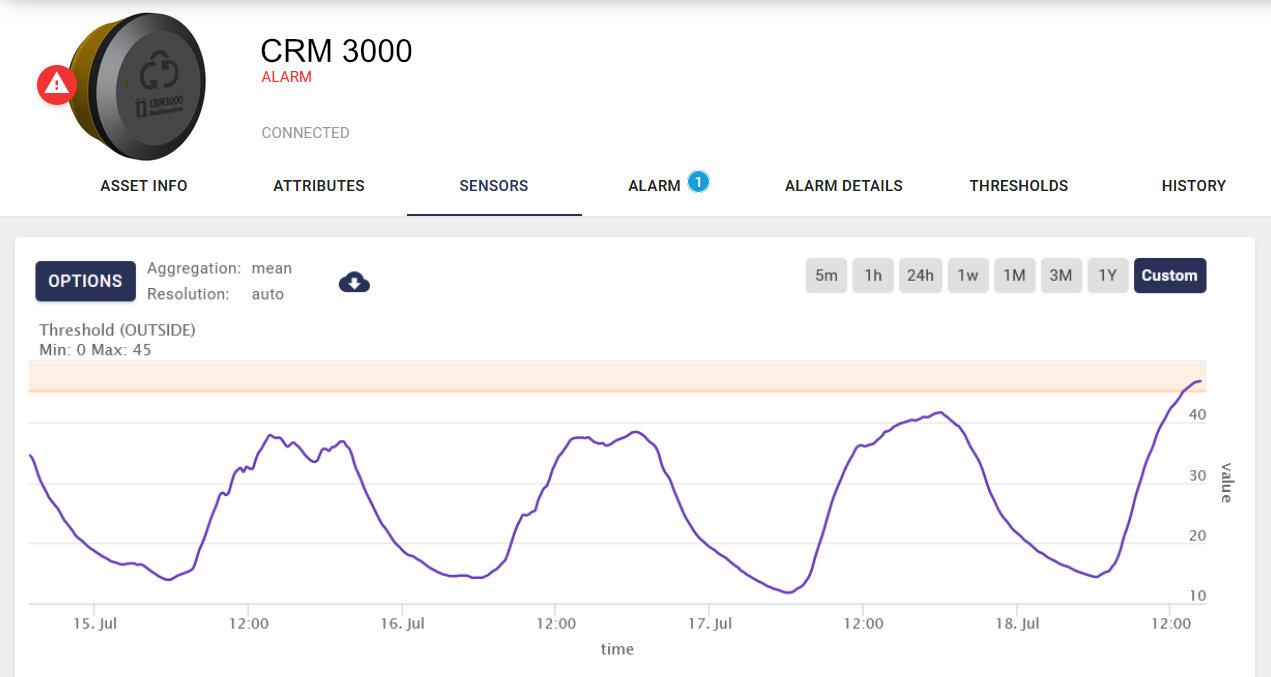

Our newest sensor, the CRM 3000, provides an extra set of eyes on the ground. Designed to measure rail temperature, it utilises our monitoring application Insight, using a wireless NB-IoT connection and a private network. The CRM 3000 keeps you up-to-date constantly and whenever the track reaches an unacceptable level of heat, as defined by you, our system raises an alarm.

Benefits of remote temperature monitoring

Our monitoring application Insight provides you with real-time insight into rail temperatures remotely. This gives you the chance take proactive steps to avoid unnecessary speed restrictions or stop a problem before it happens.

The CRM 3000 is developed with safety in mind. Remote monitoring removes the requirement for workers to be on track taking temperature measurements, removing them from a high-risk environment. In addition, it is quick and easy to install a CRM 3000, it simply attaches to the web of the rail magnetically in a matter of seconds, therefore minimising the amount of engineer time spent on track.

Also read:

More about the CRM 3000

Order the CRM 3000 in the MTinfo 3000 webshop