Using innovative technology to bring possessions into the 21st Century

A recent near miss, in 2017, at Camden Junction South, involving Possession Support staff and a passenger train, has prompted Network Rail to redouble its efforts to enhance safety measures for this critical workforce.

Following the recommendations of the Rail Accident Investigation Branch (RAIB) investigation, the company is now focused on reducing the risks associated with Possession Support staff working on track.

As part of this initiative, Network Rail’s Technical Authority, North and East Route, and Dual Inventive, among others, are collaborating on the Possession Limits Control project. The aim was to identify and trial innovative approaches to possession control that minimise the need for staff to be on track during possession changes, utilising products that are readily available on the market and already approved, such as the ZKL 3000 RC (Network Rail PA05/05043). This is a remote-controlled track circuit operating device (T-COD) that can help reduce the risks associated with manual interventions out on track.

2024 saw the completion of successful trials in a controlled environment followed by the first deployments of these new methodologies, ensuring that everything worked as expected in all the different types of possession in use on the network.

A successful phase one!

The first phase, T3-D, focused on protecting possessions (T3) by carrying out signalling disconnections (D).

Whilst this is a relatively common practice, to provide additional protection to line blockages, it isn’t something that was previously used to protect possessions. This process temporarily isolates segments of the signalling system. By doing so, it forces the system into a fail-safe state, preventing trains from entering or passing through the disconnected area. When a signalling disconnection occurs, the affected section of track is effectively “locked out”, ensures that no signals can be set to allow trains to enter the work zone.

Following successful testing within North & East Route, these changes are now being implemented across other routes in Network Rail. It is already delivering real safety, financial and productivity benefits.

Technology leading the way in phase two

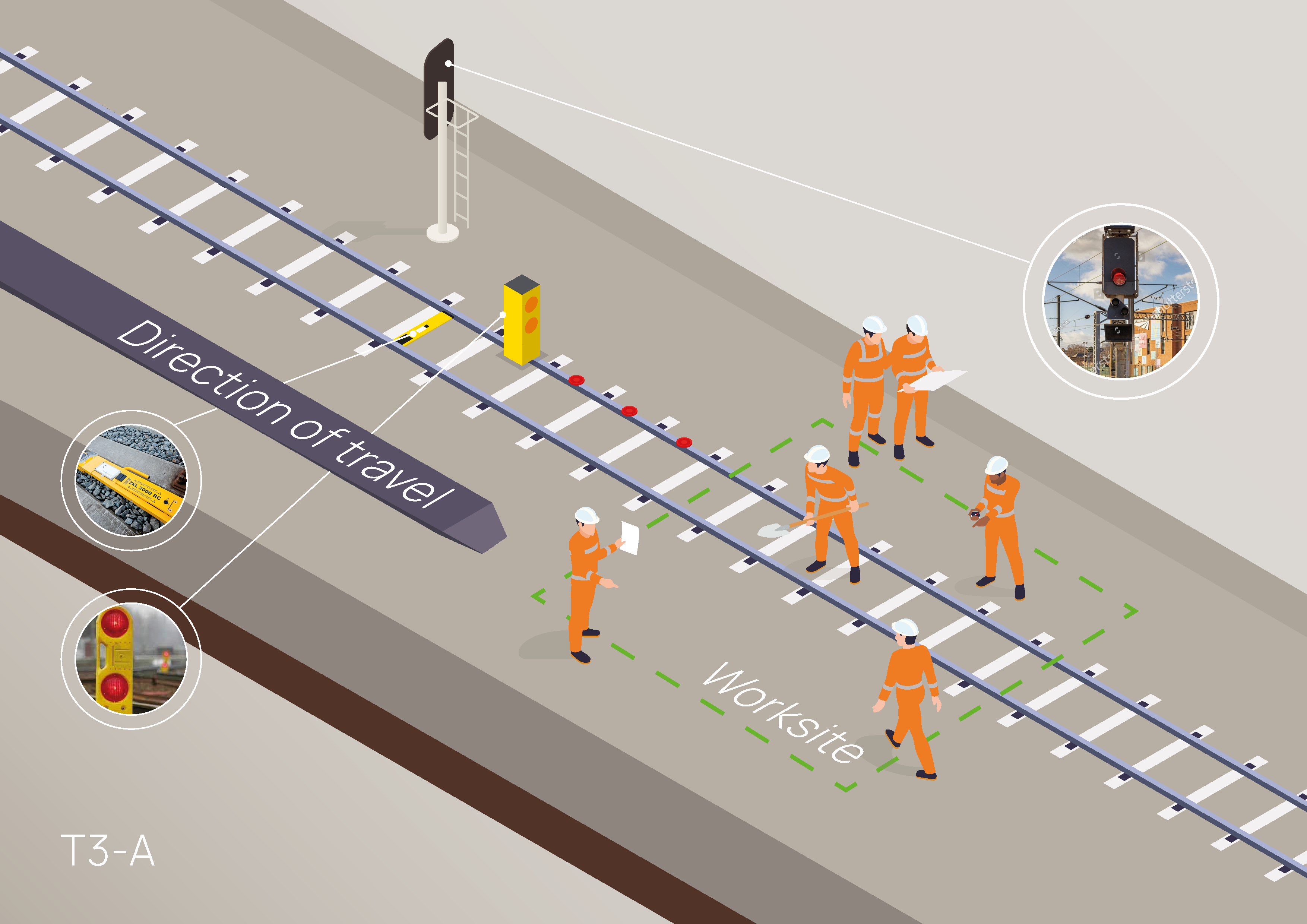

Following a successful first phase, the next step was to trial the protection of possessions (T3) using existing additional protection (A) equipment, such as the ZKL 3000 RC with the aim of replacing traditional methods such as Possession Limit Boards and detonators, again reducing the need for track workers to visit the track before protection is in place.

Once the ZKL 3000 RC is installed in track, it can be left in-situ for up to 4 years, therefore reducing boots on ballast. The device is activated using an app on a smart device to isolate the work site creating a safe work zone to allow maintenance work to take place safely.

Once the ZKL 3000 RC is installed in track, it can be left in-situ for up to 4 years, therefore reducing boots on ballast. The device is activated using an app on a smart device to isolate the work site creating a safe work zone to allow maintenance work to take place safely.

In April 2024, T3-A using ZKL 3000 RCs was trialled at Selby junction by Network Rail to develop the necessary rules for a nationwide rollout.

New ways of working for TransPennine Route Upgrade

The TransPennine Route Upgrade (TRU) team are now leading the way on adoption of this new methodology, investing in the new technology, and successfully deploying the devices on the lines between York and Leeds as part of the upgrade project.

The first T3-A installation, which went live on 6th January 2025, has marked a significant milestone in Network Rail’s Possession Limits Control project. The early results have been overwhelmingly positive, with the use of the ZKL 3000 RC in this way proving to be a major success.

Not only has this innovative technology greatly improved safety on these routes, but it has also streamlined operations, allowing for increased time on track and substantial cost savings. By automating the process of protecting work sites, staff can now focus on getting the job done efficiently, without compromising safety.

Moreover, as part of this project, the ZKL 3000 RC devices will be handed over to local teams upon completion, leaving behind a lasting legacy of safer working practices. This ensures that the benefits of this technology will continue to be felt long after the initial installation is complete, making it an invaluable investment in the future of railway operations.

Emrys Warriner, Senior Programme Manager (Safer Tracker Side Working and Operational Risk) in Technical Authority, commented:

“The leadership and investment demonstrated by the TransPennine Route Upgrade team and North & East Route sets a precedent for what can be achieved. The benefits aren’t limited to safety, financial and productivity of possessions but also enabling safer and quicker line blockages.

With collaborative working between functions, we have been able to work together to resolve issues, recycle existing technology between Routes and leave enhanced secondary protection solutions in place for our front-line workers way beyond the life cycle of the upgrade project.”

Efficiencies

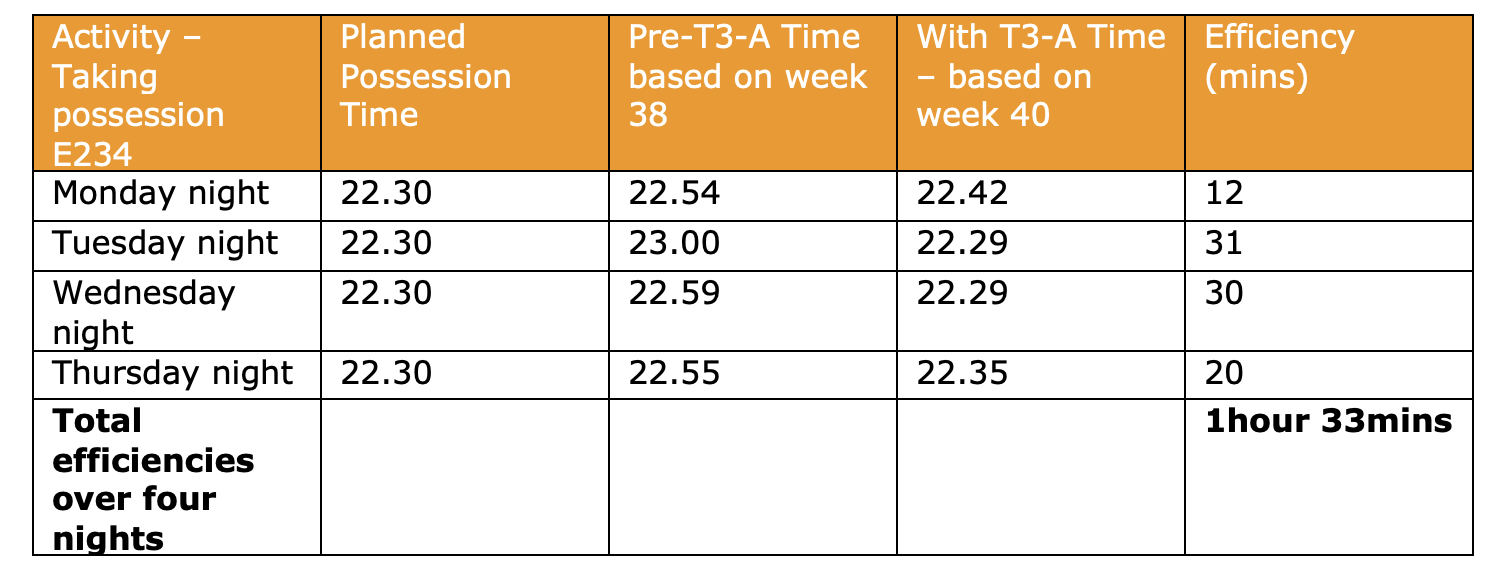

The table below shows the efficiencies made during over a four-night period on the TransPennine Route Upgrade (TRU) project.

Using the efficiencies from the TRU project, over a 52-week period a total of 80 hours and 36 minutes can be saved, allowing resources to be reallocated to other worksites.

The figures collated as part of the TRU project show that implementing the T3-A can result in a significant cost saving of 43.6% over 236 shifts.

Jo Griffiths, Programme Director on TransPennine Route Upgrade (TRU) said:

“It’s fantastic to be trialling this new innovation on TRU, as major work progresses along the route.

“Our £10.7bn scheme to transform rail travel across the North is now firmly in delivery mode, with significant improvements planned over the coming years.

“Initial findings indicate promising improvements in cost and time efficiencies, along with enhanced safety measures, all of which are crucial for a programme of this scale.”

Harnessing technology for great benefits

Adopting the new T3-A method means:

- Fewer visits to lineside to deploy the traditional methods, only one planned visit is needed to install the ZKL 3000 which can stay in situ until you change the worksite.

- Possession Support staff are less likely to place the protection in the wrong location or on the wrong line.

- Possession Support Staff no longer required to go on track at the beginning and end of every possession.

- Fewer telephone calls between the Person in Charge of the Possession (PICOP) and Possession Support staff, reducing the potential for safety critical miscommunication

- Reducing carbon footprint – by reducing the travel to worksites

By reducing boots on ballast, Network Rail are on track to creating a safer, more efficient and sustainable railway for all.

Outcome

The results of the trials have led to Network Rail revising the possession process by amending the Rail Safety and Standards Board’s industry Rule Book, enabling new safe working methods to be implemented across the UK’s rail infrastructure.