Maximum rail capacity on HSL-Zuid with smart rail temperature sensor

Summary

In recent years, there have been more prolonged periods of high temperatures which can lead to rail expanding and buckling – this is becoming an area of concern.

Infraspeed Maintenance (a joint venture between Siemens Mobility and contractor BAM Infra Rail) are responsible for managing and maintaining the rail infrastructure of HSL-Zuid (High-Speed Line South). They use Dual Inventive’s Critical Rail Monitor 3000 (CRM 3000) and online monitoring application ‘Insight’ to monitor the rail temperature of critical locations of HSL-Zuid.

This enables Infraspeed Maintenance to:

- receive notifications when the rail temperature reaches the configured alarm threshold

- obtain clear and accurate information through tailored dashboards, and

- implement good policies around necessary management measures such as temporary speed restrictions and inspections.

Problem statement

Most of HSL-Zuid consists of ballast-less track which can withstand high track loads, therefore, rail buckling does not occur in this area. However, some sections consist of ballasted track where rail expansion due to heat can lead to rail buckling, these sections of track are travelled at high speeds. For example, at the border crossing Hazeldonk trains pass at 300 km/h. In addition to this, the steel railway bridge over the Hollandsch Diep is monitored more often during periods of high temperatures.

Monitoring rail temperature and determining exactly where and when preventive measures such as temporary speed restrictions are needed is an important part of Infraspeed Maintenance’s remit. This is because lower speed exerts less force on the rail and reduces the risk of rail buckling ensuring the safety of the track and passengers.

Infraspeed Maintenance used the points heating and point machines to monitor rail temperature. However, these systems are not universally available or not always in use, so the information needed is incomplete. In addition, retrieving the required information from lots of individual systems is not efficient or user-friendly. For example, setting alarms is not possible, which meant that Infraspeed Maintenance constantly had to actively search for the information.

Solution

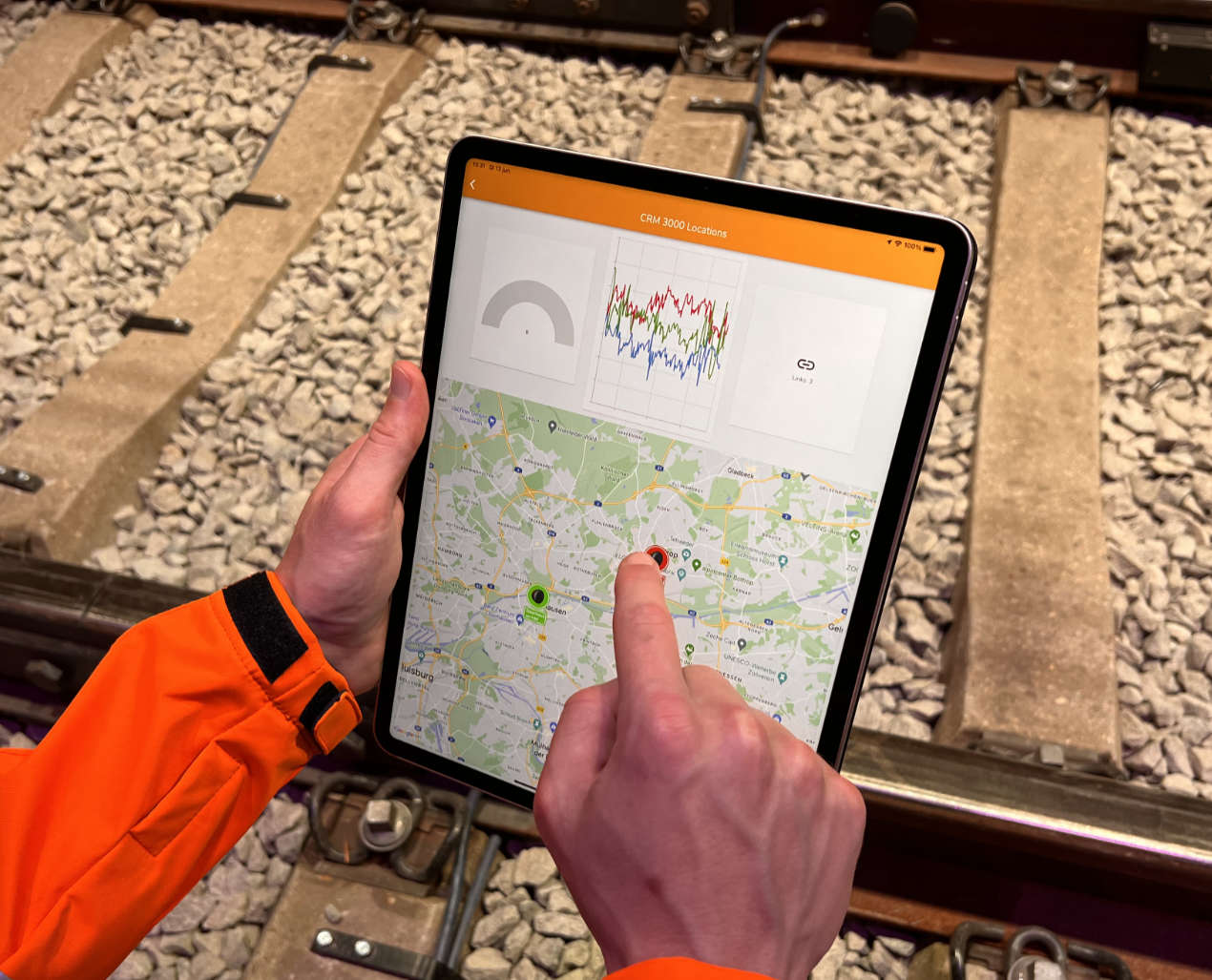

Infraspeed Maintenance is now deploying digital technology from Dual Inventive. Using the CRM 3000 temperature sensors and having access to the online monitoring application Insight enables them to monitor the rail temperature of critical locations and act accordingly.

The CRM 3000 is battery-powered, it attaches to the rail with a magnetic fixing and accurately measures rail temperature with an integrated sensor. The measured values are transmitted via the NB-IoT network to the online monitoring application Insight. If the temperature reaches the preconfigured alarm threshold, Insight sends a notification to the user so that immediate action can be taken.

There are several dashboards available, including a geographical map showing the status of all CRM 3000s in the field. Also, users can create their own dashboards tailored to their personal informational needs.

Jeffrey van Bezouw, Maintenance Engineer at Infraspeed Maintenance said:

“Setting threshold values is simple and I have created a number of dashboards myself. The way Insight alerts you is convenient, it’s an excellent tool to use to monitor data.”

Added value

The deployment of CRM 3000 rail temperature sensors and the Insight monitoring application provides significant added value, such as:

- Having access to automated notifications when configured alarm values are reached.

- Having the data supplied to determine whether inspections are needed.

- Minimising the number of necessary speed limits.

- Providing users with important information.

- Missing or incomplete information is a thing of the past.

- Being able to create different dashboards tailored to informational needs.

- Having the ability to establish a clear policy around rail temperature.

Niek den Hollander, Project Manager at Infraspeed Maintenance, said:

“The system helps us determine when and where to set speed limits giving us peace of mind in our decision-making process and operations. It also protects us from risk, increasing rail and passenger safety.”

Photo HSL: © Eugene Winthagen / ANP